Material utilization of the waste polymer by pyrolysis

Pyrolysis is:

What is the output of pyrolysis?

Crushed tires will be used as input material. The dialy operating capacity is 50 tons of processed second-hand tires.

CARBON / GAS / OIL / CORDS

CARBON: produces the highest profit, and there is currently a shortage of 25 milion tons of carbon on the marker.

Market analysis and demand prognosis

GAS

10% of pyrolytic product

It i sused in the electricity production and simultaneously in the production of hot or cold water for air conditioning.

ALTERNATIVE A

CARBON

35-40% of production

It is used in the rubber industry as an absorbent material in petroleum refineries, in chemical production and in pharmaceutical manufacture as a pigmenr for the production of plastics, etc.

ALTERNATIVE B

OIL

50-55% of production

It can be used as an energy carrier in its raw state. The heat generated by the cogeneration process can also be used for the production of domestic hot water and for air conditioning.

ALTERNATIVE C

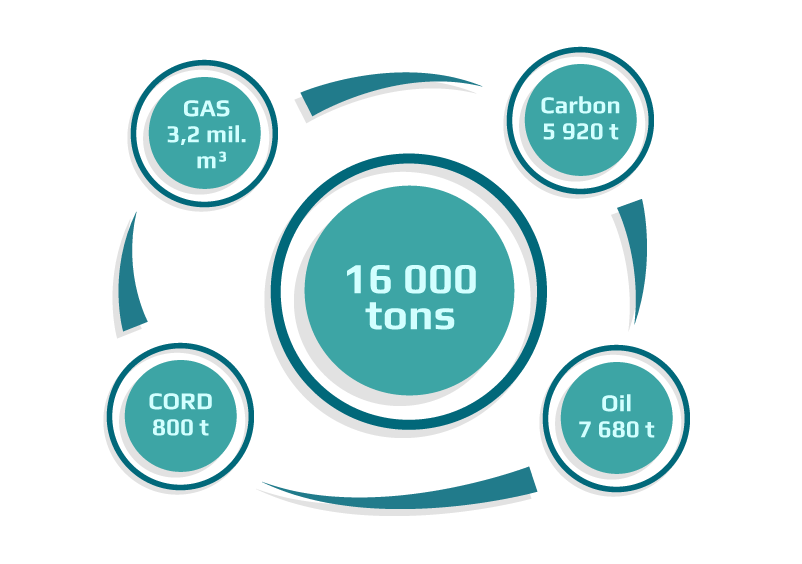

CAPACITY OF MANUFACTURING EQUIPMENT

Muffle furnace processes annually 16 000 tons of pulp and produces the following products:

Pyrolysis gas will be compressed to 0.25 MPa, stored in gas tanks and then trasferred to combustion of CHP.

Muffle furnace coal is collected in closed containers an transported by a fork-lift truck to a carbon store from where it will be shipped to costomers.

The pyrolytic oil will be transported by gravity piping to underground storage tanks for temporary storage, and it will be transported to the customer for further proccessiing.

OPERATING REQUIREMENTS

The input material is crushed tires. The daily operating capacity is 50 tons of processed used tires:

UNIPRO SPE01 SE

Korunní 2569/108, Vinohrady,

101 00 Praha 10, Česká republika

IC: 075 80 592

Phone: +420 608 701 246,

+420 774 618 639

Fax: +420 227 077 680

E-mail: info@uniprospe.eu